Kana zvasvika pakuita bhodhoro kugadzira molds, chinhu chekutanga chinofunga nezvacho chiri chekutanga chiumbwa, chiumbwa, muromo wakaumbwa uye pasi peumbi. Kunyangwe musoro wekuputika zvakare nhengo yemhuri yemald, nekuda kwehukuru hwayo diki uye mutengo wakaderera, ijunior yemhuri yeMold uye haina kukwezva kutarisa kwevanhu. Kunyangwe musoro wekuridza mudiki, basa rayo harigone kurerutswa. Iyo ine basa rinozivikanwa. Zvino ngatitaure nezvazvo:

Vangani kufema varipo mune imwe blower?

Sezvinoreva zita racho, basa remusoro rinoputika rekuputika rakamanikidza mhepo kuti riite kuti inyatsogadzira musoro, kuti ubudirire mumhepo.

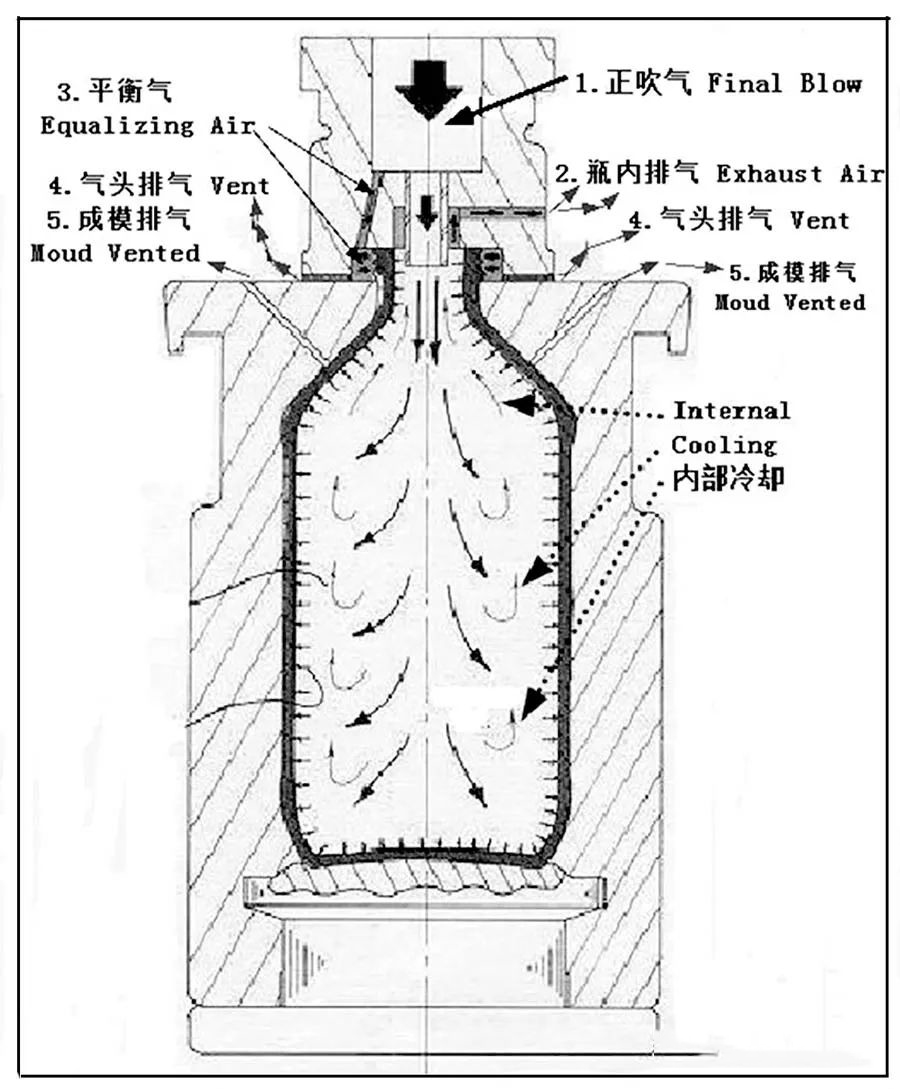

Ngatitorei kutarisa kuti ndeipi mhando yemhepo iri munzira yekuputika:

1. Kupedzisa kuputika: Bhuroputsa yekutanga mold chigadziko kuti iite pedyo nemadziro mana uye pasi pechiumbwa, uye pakupedzisira ita iyo thermo bottle chimiro;

2. Kupera kunze kweMold: Kupera mweya kubva mukati mehombodo yekupisa kusvika kunze kwedhorobha rekuputika

3. Izvo zvakabatana zvakananga kumuromo webhodhoro kubva pane zvakanaka kuputika chikamu. Mhepo iyi ndeyekuchengetedza muromo webhodhoro kubva kuhurongwa. Inonzi kuenzana mhepo muindasitiri;

4

5. Kutyaira neakanaka kuridza simba, iyo yakabatanidzwa isina chinhu iri padyo neumbwa. Panguva ino, gasi munzvimbo pakati pechinhu chisina chinhu uye chiumbwa chakasungirirwa uye chinopfuura nepakati pehupfumi chaicho kana chejector ecuum. kunze (kuumbwa kwakareruka) kudzivirira gasi kubva pakugadzira iyo yemhepo cushion mune ino nzvimbo uye inodzora kumhanya kwekugadzira.

Izvi zvinotevera zvinyorwa zvishoma pane zvakakosha kudya uye kuneta.

2.

Vanhu vanowanzo bvunza kuti vawedzere kumhanya uye kushanda kwemuchina, uye mhinduro iri nyore ndeiyi: ingowedzera kudzvinyirira kwekuridza kwakanaka uye kunogona kugadziriswa.

Asi hazvisizvo. Kana isu tiri kuputika mhepo nekumanikidzwa kwakanyanya kubva pakutanga, nekuti yekutanga mold isina kuwirirana neyekuumbwa madziro panguva ino, uye pasi peMold haina kubata isina chinhu. Iyo isina chinhu inoburitsa hombe kukanganisa simba, iyo ichakonzera kukuvara kune isina chinhu. Naizvozvo, kana kuridzwa kwakanaka kunotanga, kunofanirwa kuridzwa mukati nekudzvanywa kwemhepo yekudzvinyirira kutanga, kuitira kuti kuumbwa kwekutanga kwakapepetwa uye kuswededzwa kumadziro uye pasi peumbi. gasi, kugadzira kutenderera kwekutonhorera kunotonhora muTermos. Maitiro ekubhadhara ari seinotevera:.

1 Pakutanga kwekuridza kwakanaka, kuridza kwakanaka kunovhuvhuta kwakasviba uye kunamatira kumadziro eyekuumbwa. Yakadzika mhepo yekumanikidza (semuenzaniso 1.2kg / cm²) inofanira kushandiswa panguva ino, iyo inokonzeresa inenge makumi matatu muzana yekuputika nguva yekurovera nguva kugoverwa,

2. Muchikamu chekupedzisira, nguva yemukati inotonhorera yeTermos inoitwa. Iyo yakanaka yekuputika mhepo inogona kushandisa yakakwirira yemhepo kumanikidzwa (yakadai se2,6kg / cm²), uye kugoverwa munguva yenguva ndeye 70%. Paunenge uchirovera zvakadzama kumanikidza mhepo yemitambo, nepo ichipinda kunze kwemuchina kuti itonhore pasi.

Ichi chidimbu chechipiri chechiitiko chekuputika kwekuputika kwete kungoita kuti kuumbwa kweTermobottle nekuputika kusavapo kwekutanga, asi zvakare nekukurumidza kubvisa kupisa kwerudzi rwekuumbwa kusvika kunze kwemuchina.

Matatu ezvinyorwa zvekusimbisa kuneta kwemabhodhoro ekupisa

Vamwe vanhu vanozobvunza kuti vawedzere kumhanya, chero bedzi mhepo inotonhorera inogona kuwedzerwa?

Muchokwadi, hazvisizvo. Isu tinoziva kuti mushure mekunge kutanga kuumbwa kushoma kunoiswa muMold, kupisa kwemukati kuchiri kwakakwira kusvika pa1160 ° CLE C [1], iyo yakangofanana neyekushisa tembiricha. Naizvozvo, kuitira kuti uwedzere kumhanya kwemushini, kuwedzera pakuwedzera mweya wekutonhora mukati meiyo Thermos, iri imwe yemakiyi ekudzivirira kusvibisa kweiyo thermos uye kuwedzera kumhanya kwemuchina.

Zvinoenderana nekuferefetwa uye kutsvagisa kweiyo Ongorora kambani, kupaza kwakadzika kwezvinhu zve12% (Pazasi pokuputika) Maakaunzi maakaunzi e7% (kutonhora kwemukati) [2].

Kunyangwe kutonhorera kwemukati uye kupisa kwemhepo kwemhepo yekuputika kwemhepo chete maakaundi 7%, iyo yakaoma iri mukutonhora kwekushisa kwetembiricha muTermos. Iko kushandiswa kwekutenderera kwemukati kutenderera ndiyo chete nzira, uye dzimwe nzira dzekutonhora dzakaoma kutsiva. Iyi nzira inotonhorera inonyanya kubatsira kune yakakwirira-yekumhanyisa uye yakakora-yakakora mabhodhoro.

Zvinoenderana nekutsvagirwa kweKambani yeAmmart, kana kupisa kwacho kwekutsvagisa kubva kuTermos kunogona kuwedzerwa ne130%, mukana wekuwedzera kumhanya kwemuchina unopfuura gumi muzana zvichienderana nemhando dzakasiyana dzemabhodhoro. . Inogona kuoneka kuti yakakosha sei kutonhora muTermos!

Ndingaitei kuti ndidzivise kupisa kwakawanda kubva kuRERMOS?

Iyo yekubiridzira gomba ndiro yakagadzirirwa kubhodhoro kubhodhoro kugadzira muchina oparidza kuti gadzirise saizi ye gasi rakanyanyisa. Iro renji rakatenderedzwa ne5-7 maburi emadhiri akasiyana akadonhedzwa pairi uye akagadziriswa pamhepo inovhuvhuta musoro bracket kana musoro wemhepo uine screws. Mushandisi anogona kugadzirisa saizi yehuswa hwehuswa maererano nehukuru, chimiro uye bhodhoro kugadzira maitiro echigadzirwa.

2 Zvinoenderana nerondedzero iri pamusoro, kururamisa nguva yekutonhorera yenguva (kutonhora kwemukati) panguva yekuputika kwakanaka kunogona kuwedzera kumanikidzwa kwemhepo uye kugadzirisa kumhanya uye mhedzisiro yekudzora kutonhora.

3 Edza kuwedzera nguva yakanaka yekuputika pane iyo yemagetsi nguva,

4 Munguva yekurova, mweya wakatenderedzwa kuti uvandudze kugona kwayo kana kushandisa "mweya unotonhora" kuputika, etc. Vaya vane hunyanzvi mumunda uyu vanogara vachiongorora hutsva hunyanzvi.

chenjera:

Mukudzvinyirira & kuputika nzira, sezvo punch ichirova zvakanyatsonaka mumvura, punch ine simba rakasimba, uye tembiricha yemadziro emukati yakaderedzwa zvakanyanya, anenge ari pazasi 900 ° C [1]. Mune ino kesi, haisi dambudziko rekutonhora uye kupisa kupfeka, asi kuchengetedza tembiricha muTermos, saka kutarisisa kunofanirwa kubhadharwa kune dzakasiyana nzira dzekurapa dzekugadzira mabhodhoro.

4. Kureba kwese kwekutonga bhodhoro

Kuona nyaya iyi, vamwe vanhu vanobvunza kuti kukwirira kwebhodhoro regirazi ndiko kufa + kuumbwa, kunoita kunge uine zvishoma kuita nemusoro wekuridza. Muchokwadi, hazvisizvo. Mugadziri webhodhoro wakazvionera mhepo: Kana musoro wekuputika uchirova mhepo panguva yepakati nepakati, iyo matsvuku erimmos ichafambisa kumusoro pasi pemhepo yakamanikidzwa, uye chinhambwe ichi chinofamba chinoshandura bhodhoro regirazi. kureba kwe. Panguva ino, formula yekukwirira kwedhorobha regirazi rinofanira kuchinjwa ku: kuumbwa + kuumbwa + kure kubva kune hottle rinopisa. Kureba kwakazara kwebhodhoro regirazi kunovimbiswa kwazvo nedzidzo yakadzika yeziso rekupedzisira remusoro wekuputika. Kukwirira kunogona kupfuura chiyero.

Kune maviri mapoinzi ekukwevera kutarisa kune maitiro ekugadzira:

1. Musoro unoputika wakapfekwa nebhotwe rinopisa. Mold painogadziriswa, inowanzoonekwa kuti kune denderedzwa remuromo wemuromo-rakaumbwa nemaruva emukati kumeso kwemukati. Kana mucherechedzo wakadzika kwazvo, zvinokanganisa kukwirira kwakawanda kwebhodhoro (bhodhoro richava rakareba), ona nhamba 3 yasara. Ive nekuchengera kudzora muzvipfeve kana uchigadzirisa. Imwe kambani inodonha mhete (inomira mhete) mukati maro, iyo inoshandisa mesimbi kana isingamwari zvinhu, uye inogara ichitsiviwa kuti ive nechokwadi chekureba kwehombodo yegirazi.

Musoro unoputika kakawanda unodzokera kumusoro uye pasi pakawanda frequency kuti udzokere pakuumbwa, uye chiso chemusoro wekuputika chinopfekwa kwenguva yakareba, icho chichakanganisa kureba kwebhodhoro. Hupenyu hweBasa, ita kuti urefu hwese hwegirazi regirazi.

5. Ukama pakati pekuputika musoro chiitiko uye kuenderana nenguva

Kuita zvemagetsi zvinoshandiswa zvakanyanya mumachira emazuva ano kuita michina, uye musoro wemhepo uye nekuputika kwakanaka kune nhevedzano yekugadzirisa nezvimwe zviito:

1 yekupedzisira kuputika pane

Iyo nguva yekutanga yekurova kwakanaka inofanira kutsanangurwa maererano nehukuru uye chimiro chegoridhe yegirazi. Kuvhurwa kwekuputika kwakanaka ndeye 5-10 ° Pashure pane iyo yekuputika musoro.

Iyo yekurova musoro ine zvishoma bhodhoro stabilization mhedzisiro

Pane dzimwe bhodhoro rekare kugadzira michina, iyo pneumatic mhedzisiro yekuvhura yekuumbwa uye kuvhara haina kunaka, uye bhodhoro rinopisa richazunza kuruboshwe uye hurefu pakazaruka. Tinogona kugura mhepo pasi pemusoro wemhepo kana iyo mold yakavhurwa, asi mweya uri mumusoro wemhepo hauna kutenderwa. Panguva ino, musoro wemhepo uchiramba uchigara pakaumbwa, uye kana chiumbwa chakati chavhurwa, chinoburitsa kudhonza kushoma nemusoro wemhepo. Simba, iyo inogona kutora basa rekubatsira iyo yekuumbwa nekuvhura uye kubhururuka. Nguva yacho ndeiyi: Musoro wemhepo wave anenge gumi ° mushure mekuvhura kweMold.

Kurongedza zvinomwe zvekuputika musoro kukwirira

Patinoisa iyo gasi yemusoro mwero, iyo general kuvhiyiwa ndeye:

1 Mushure mekunge chiumbwa chakavharwa, hazvigoneke kuti musoro wemhepo kuti unyure kana mhepo ichirovera musoro bracket yabatwa. Varombo vakakodzera vanowanzoita kuti muswe pakati pemusoro wemhepo uye kuumbwa.

2 Pakazadzwa chiumbwa chakavhurika, chicharova musoro wekuputika uchaita kuti musoro wekuputika uchikwevera zvakadzika, zvichikonzera kuridza musoro musoro wekuridza uye kuumbwa kuti usimbiswe. Nekuda kweizvozvo, mechanism ichakurumidza kupfeka kana kukonzera kuumbwa kwemota. PaGob Brotle Kugadzira Machine, inokurudzirwa kushandisa Special Set-up Blowheads (Set-up Flowheads), iyo ipfupi pane yakajairwa mhepo musoro (runyararo Ray), nezve zero zero zero.8 mm. Iko kuiswa kwemusoro wemusoro kukwirira kunofanirwa kutariswa maererano nezvinhu zvakazara senge saizi, chimiro uye kugadzira nzira yechigadzirwa.

Zvakanakira kushandisa seti yegesi yegesi:

1 kukurumidza setup inochengetedza nguva,

2 iyo yekuisa yeiyo mechenic nzira, iyo inoenderana uye chiyero,

3 Myunifomu zvigadziriso zvinoderedza urema,

4 Inogona kuderedza kukuvadzwa kwemuchina-kugadzira michina uye kuumbwa.

Ziva kuti kana uchishandisa iyo Gasi Musoro weGige, panofanirwa kunge paine zviratidzo zviri pachena, zvakadai sependi iri pachena kana kuti dzakanyorwa nenhamba dzemazwi nemusoro wenyaya

8. Calibration pamberi pemusoro wekuputika unoiswa pamushini

Musoro wekuridza unosanganisira kuridza zvakanaka (wekupedzisira kurova), kuputika kutenderera kwekuneta (kuputika kwemusoro) uye kuenzanisa mhepo (kuenzanisa mhepo) panguva yekuputika kwakanaka. Chimiro chakanyanya kuoma uye chakakosha, uye zvakaoma kuzvichengeta neziso rakashama. Naizvozvo, zvinokurudzirwa kuti mushure mekunge idzva blower kana kugadzirisa, zvakanaka kuti uzviyeuke zvekutarisa kuti chidimbu chega chega chega chega chinyoreso, kuitira kuti muve nechokwadi chekuti mhedzisiro yacho inosvika pakukosha kwakanyanya. Makambani ekunze ekunze ane zvishandiso zvakakosha kuti uone. Isu tinokwanisa zvakare kugadzira iyo yakakodzera gasi yemusoro calibration mudziyo zvinoenderana nemamiriro ekunze, izvo zvinonyanya kushanda. Kana vatinoshanda navo vachifarira izvi, vanogona kureva patent [4]: nzira uye zvishandiso zvekuyedza dual-stage bload paInternet.

9 inogona kuve yakarongedzwa kuremara kwemusoro wegesi

Kuremara nekuda kwekurongeka kwakashata kwekurova kwakanaka uye kuridza musoro:

1 kuputika kupera

Kuratidzwa: Muromo weBhodhoro Bullges kunze (maboji), iyo Chikonzero: Iyo Mhepo Yakasarudzika yemusoro wekurova wakavharwa kana kusashanda.

2 Crozzzled Solaling Pamusoro

Chitarisiko: Mwenje wakadzika pamhepo yemuromo webhodhoro, chiso chomukati chechiratidzo chemusoro wekuputika chakapfekwa zvakanyanya, uye bottle inopisa inofamba ichikwira kana ichivhuvhuta, uye inokonzerwa nekukanganisa.

3 Bent mutsipa

Performance: Mutsipa webhodhoro zvinoda uye zvisina kurongeka. Chikonzero ndechekuti mhepo inovhuvhuta musoro haina kunyoroveswa kuti ipise kupisa uye kupisa hakuna kudzingwa, uye bhodhoro rinopisa rakapfava uye rakaremara mushure mekunge ratemwa.

4 kuputira pombi chiratidzo

Zviratidzo: Kune kukwenya pamadziro emukati kwehuro bhodhoro. Chikonzero: Usati waridza, pombi yekurova inobata chiratidzo chekuridza pombi chakaumbwa pamadziro emukati webhodhoro.

5 kwete inovharira muviri

Zviratidzo: zvisina kukwana kugadzirwa kwemuviri webhodhoro. Inokonzera: isina kukwana mhepo yekumanikidza kana kwenguva pfupi yekuputika kwakanaka, kuvharidzirwa kwekuneta kana kusagadziriswa zvisina kufanira kwemakomba ekupedza simba.

6 kwete kuzunguzika mbambo

Performance: Bhodhoro regirazi harina kunyatsoumbwa, rikakonzerwa nekusvibiswa kwehombodo yebhofu. Zvikonzero: Hazvina kukwana kutonhora mubhodhoro rinopisa, kuvharidzirwa kwekunyepedzera kana kusarongeka kwekugadziriswa kwegomba rakaperuka reiyo inopenya plate, uye pfudzi rakapfava reganda rinopisa.

7 isina kukodzera verticality (bhodhoro rakakombama) (leaner)

Performance: Iko kutsauka pakati pemuromo webhodhi remuromo uye mutsetse webhodhoro rebhodhoro, zvichikonzera bhodhoro rinopisa, uye hotwe rinopisa rakapfava kune rimwe divi, zvichikonzera kuti ritsauke kubva pakati uye deform.

Izvi zviri pamusoro ndezvangu chete maonero angu, ndapota ndiruramise.

Kutumira Nguva: Sep-28-2022